Storm Mixer recommends that the injectors be placed as far upstream of the mixer as practical.

Wafer mixers will provide significantly better mixing when:

- The chemicals have the opportunity to disperse in the pipeline due to pipeline turbulence and chemical diffusion.

- The dispersed chemical can directly impact the wafer mixer and be subjected to the shearing forces of the wafer mixer.

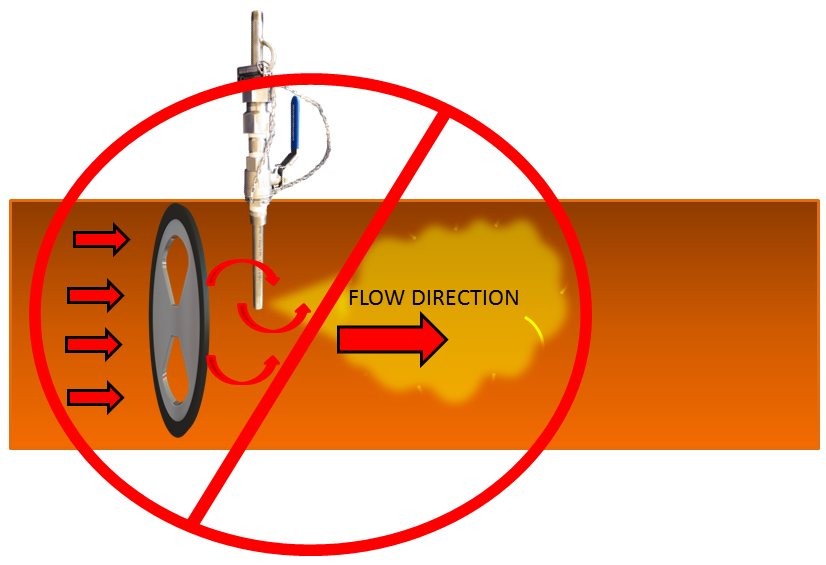

There has been a trend by some suppliers to recommend placing the injector inside or after the mixer, which defies logic. All mixers create turbulence and continue mixing after the mixer. There is much more mixing energy available when passing the chemicals through the mixer.

The one exception could be made for coagulation/flocculation injection, where there could be concern about damaging the floc formation by passing through a mixer. For most chemicals (chlorine, ammonia, antiscalants) add the chemicals well ahead of the mixer.

Storm Mixer can offer a wide range of injectors to complement your wafer static mixer application. Contact Storm Mixer for a quotation!

Threaded injector with integral ball check valve

Removable style corporation stop style injector

Flanged injector