Choosing a wafer static mixer

There are several steps to choosing an appropriate wafer static mixer:

1. Choose the appropriate material of construction.

2. Size the mixer.

3. Choosing injectors

Choose appropriate material of construction:

It is a good idea to use a wafer mixer that is constructed out of materials that are compatible with the chemical that is being added. That being said, when adding very small amounts of chemicals such as chlorine (usually added in parts per million quantities) Iit is often possible to use a wafer mixer that is constructed from an incompatible material such as stainless steel, as the amount of chlorine is so small that it becomes inconsequential.

Whenever possible, it is best to match the pipeline material. A steel or ductile iron pipeline can use a stainless steel or epoxy coated wafer mixer. A PVC wafer mixer can also be used if the pipeline is properly supported to eliminate mechanical stresses on the wafer mixer.

Size the mixer

The range of flow in a pipeline should between about 2 ft/sec and 10 ft/sec

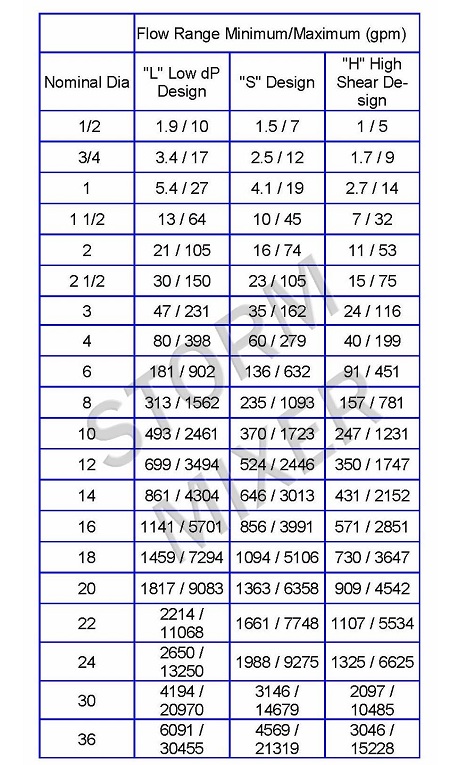

To calculate velocity in a pipeline, use the chart listed below, which will provide the flow range a mixer can accommodate. This flow range is sized for a maximum 5 psi pressure drop.

Storm Mixer offers three variations on the mixer, to optimize the mixer for several flow ranges.

Wafer mixers work best when they can be optimized for a particular flow rate. Many water applications have a large range of flow rates--High peak flows and very low minimum flow rates. If the minimum flow rates are outside of the range of a wafer mixer, mixing of the solution may suffer or may be inadequate.

Injectors

Storm Mixer recommends that injectors be installed upstream of the wafer static mixers. If this is not possible, we can integrate your injection system into the wafer mixer. Contact Storm Mixer for more information or specifications.