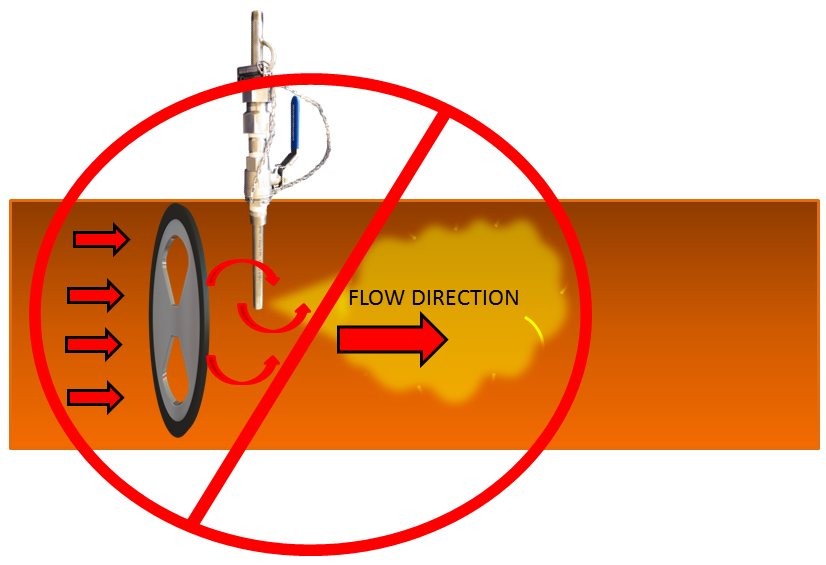

Storm Mixer recommends that the injectors be placed as far upstream of the mixer as practical.

Wafer mixers will provide significantly better mixing when:

- The chemicals have the opportunity to disperse in the pipeline due to pipeline turbulence and chemical diffusion.

- The dispersed chemical can directly impact the wafer mixer and be subjected to the shearing forces of the wafer mixer.

There has been a trend by some suppliers to recommend placing the injector inside or after the mixer, which defies logic. All mixers create turbulence and continue mixing after the mixer. There is much more mixing energy available when passing the chemicals through the mixer.

The one exception could be made for coagulation/flocculation injection, where there could be concern about damaging the floc formation by passing through a mixer. For most chemicals (chlorine, ammonia, antiscalants) add the chemicals well ahead of the mixer.

Storm Mixer can offer a wide range of injectors to complement your wafer static mixer application. Contact Storm Mixer for a quotation!

Threaded injector with integral ball check valve

Removable style corporation stop style injector

Flanged injector

(Above: PVDF wafer static mixer)

Storm Mixer can provide a wide variety of custom wafer mixers and short lay length mixers.

Available in almost any type of material with any type of special features or injectors.

Contact us for a custom quotation

PTFE lined wafer static mixer with integral injector for acid injection to produced water for pH control.

Storm Mixer manufactures a range of pipe style static mixers. These can be seen at www.stormMix.com

Stainless steel wafer style static mixer

Storm Mixer’s wafer mixer is the perfect solution when space and lay length are at a premium. Designed to fit between flanges, this compact static mixer provides excellent mixing and low cost in a space saving package

The stainless steel wafer mixer is available in a range of sizes from 1/2” to 36”

With a wide range of options and styles available, Storm wafer style mixers can easily be adapted to meet the exacting needs of your specific application.

![]() Download the SS wafer mixer brochure (780 kb)

Download the SS wafer mixer brochure (780 kb)

BENEFITS

· Compact Design.

· Low cost, economic design reduces static mixer costs.

· Broad chemical compatibility allows for a wide range of uses.

· Can be customized to fit your requirements.

· Low energy consumption.

· Easy installation.

· No maintenance.

FEATURES

· Easy installation in pipelines. Fits within the bolt circle of pipe flanges.

· All 316 SS construction insures chemical compatibility with a wide range of chemicals.

· Unique design of mixing elements provide high levels of mixing in a short lay length.

· Adaptable to both liquid and gas stream applications.

· Available in standard and low pressure drop versions.

APPLICATIONS

· Chlorine

· Ammonia

· Flocculants

· Antiscalants

· Fluoride

Wafer mixers work best when mixing aqueous/low viscosity chemicals. For viscous chemicals such as concentrated acids and polymers, a pipe style static mixer provides superior performance.

Epoxy coated wafer mixers available in a range of sizes from 10” to 36”.

Storm Mixer’s wafer mixer is the perfect solution for larger wafer mixers when space and lay length are at a premium. Designed to fit between flanges, this compact static mixer provides excellent mixing and low cost in a space saving package.

With a wide range of options and styles available, Storm wafer style mixers can easily be adapted to meet the exacting needs of your specific application.

![]() Download Epoxy coated wafer mixer brochure (775 kb)

Download Epoxy coated wafer mixer brochure (775 kb)

BENEFITS

· Compact Design.

· Low cost, economic design reduces static mixer costs.

· Broad chemical compatibility allows for a wide range of uses.

· Can be customized to fit your requirements.

· Low energy consumption.

· Easy installation.

· No maintenance.

FEATURES

· Easy installation in pipelines. Fits within the bolt circle of pipe flanges.

· Epoxy coated construction insures chemical compatibility with a wide range of chemicals.

· Unique design of mixing elements provide high levels of mixing in a short lay length.

· Adaptable to both liquid and gas stream applications.

· Available in standard and low pressure drop versions.

APPLICATIONS

· Chlorine

· Ammonia

· Flocculants

· Antiscalants

· Fluoride

Epoxy coated wafer mixers available in a range of sizes from 10” to 36”. For smaller sizes we recommend stainless steel or PVC construction.

Available with a wide range of injectors and additive ports

Epoxy Coated Carbon Steel. Scotchkote™ 134 is a standard coating, however other coatings are available.

Wafer mixers work best when mixing aqueous/low viscosity chemicals. For viscous chemicals such as concentrated acids and polymers, a pipe style static mixer provides superior performance.